I.Is the $100 Billion Power Tool Battery Market Trapped in “Brand Prisons”?

In 2025, the global power tools market exceeds $35 billion (source: Statista 2025 Industry Report). However, “battery brand lock-in” has become a core pain point restricting industry efficiency and user experience—after buying a DeWalt drill, you can only repeatedly purchase high-priced batteries from the same brand; when switching to a Makita chainsaw, old batteries become useless scrap due to mismatched interfaces or communication protocols.

Power tool battery standardization has thus become a shared demand of the industry and users. Semrush data shows: “power tool battery standardization” gets 6.6K monthly searches in the US and over 6.7K globally; meanwhile, related keywords like “universal power tool battery”, “power tool battery compatibility”, and “power tool battery interchangeability” are also surging in popularity, directly reflecting the market’s urgent demand for “breaking brand restrictions and achieving battery universality”. According to Market Research Future, the compound annual growth rate of the power tool battery standardization market will reach 8.2% from 2025 to 2030, indicating its long-term potential.

II.3 Core Pain Points of Power Tool Batteries (Invisible Traps of Cost & Frustration)

Pain Point 1: Brand Lock-in, Batteries Become “Disposable”

After buying a Brand A (e.g., DeWalt) hammer drill, if the battery is damaged, you can only repurchase the original battery from that brand, which typically costs $100-$150; once you switch to a Brand B (e.g., Milwaukee) chainsaw, the old battery becomes “e-waste” due to mismatched physical interfaces or internal communication protocols. This “brand lock-in” traps users in a single brand ecosystem and forces repeated high costs. Google searches for “power tool battery not working with other brands” exceed 5,000 monthly, and searches for specific brand combinations like “DeWalt battery with Makita tool” and “Milwaukee battery cross-brand use” are also increasing year by year, proving it’s a widespread industry pain point.

Pain Point 2: False Compatibility Claims, “Universal Batteries” Are Not Universal

Some sellers claim “universal power tool batteries” fit multiple brands, but in actual use, tools frequently report errors, torque drops sharply, or even damage motors. User James’ experience is representative: he bought a “universal battery” claiming compatibility with 5 major brands like DeWalt, Makita, and Bosch, only to burn out his drill’s circuit board (costing over $200 to repair)—the root cause is that these batteries don’t follow a unified power tool battery standard and only achieve “physical interface compatibility” while ignoring the matching of core protocols such as voltage regulation and current protection.

Pain Point 3: Lack of Maintenance Awareness, Battery Life “Halved”

Even if you choose standardized batteries, users often shorten battery life from 3 years to 1 year due to “lack of maintenance knowledge”. For example, NiCd batteries develop “memory effect” without timely discharge, leading to permanent capacity loss; lithium batteries accelerate the degradation of positive electrode materials when stored fully charged for a long time; NiMH batteries are extremely sensitive to over-charging and over-discharging. Yet Google “power tool battery maintenance tips” only get 3,000 monthly searches, far below the market’s real demand, and long-tail keywords like “how to extend power tool battery life” also leave users in an inefficient cycle of “throwing away batteries when they fail” due to lack of professional content.

III.3 Solutions: Embrace Standardization, Save Money & Hassle

Solution 1: Prioritize Universal Batteries with “Standardization Certification + Multi-Brand Compatibility”

When choosing batteries, prioritize products that follow power tool battery standardization initiatives (such as the European EBI battery interface standard, the North American Power Tool Interchange alliance certification) or clearly state “multi-brand compatibility”. Here’s a reference for universal battery selection in different scenarios:

| Battery Type | Number of Compatible Major Brands | Core Advantages | Reference Price (USD) | Certification/Technical Highlights |

| EBI-Certified Battery | 10+ | Follows European Battery Interface (EBI) | 60-90 | Unified physical interface + communication protocol |

| Universal Lithium-ion | 8+ | Fast Charging + Smart Protection Circuit | 70-110 | Adaptive voltage regulation + overcurrent protection |

| Multi-Brand NiMH Battery | 5-7 | High Cycle Life (≥1000 Cycles) | 40-70 | Low self-discharge rate + balanced charging support |

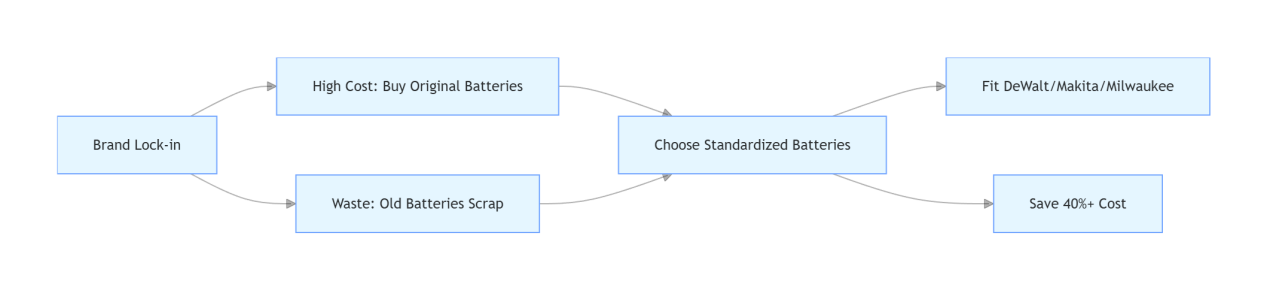

Real Case: Construction worker Mike chose an EBI-certified universal battery, which successfully fit his DeWalt drill, Makita chainsaw, and Milwaukee angle grinder. A single battery costs 40% less than original ones, saving him over $300 a year. The following diagram shows the shift from brand lock-in to standardized batteries:

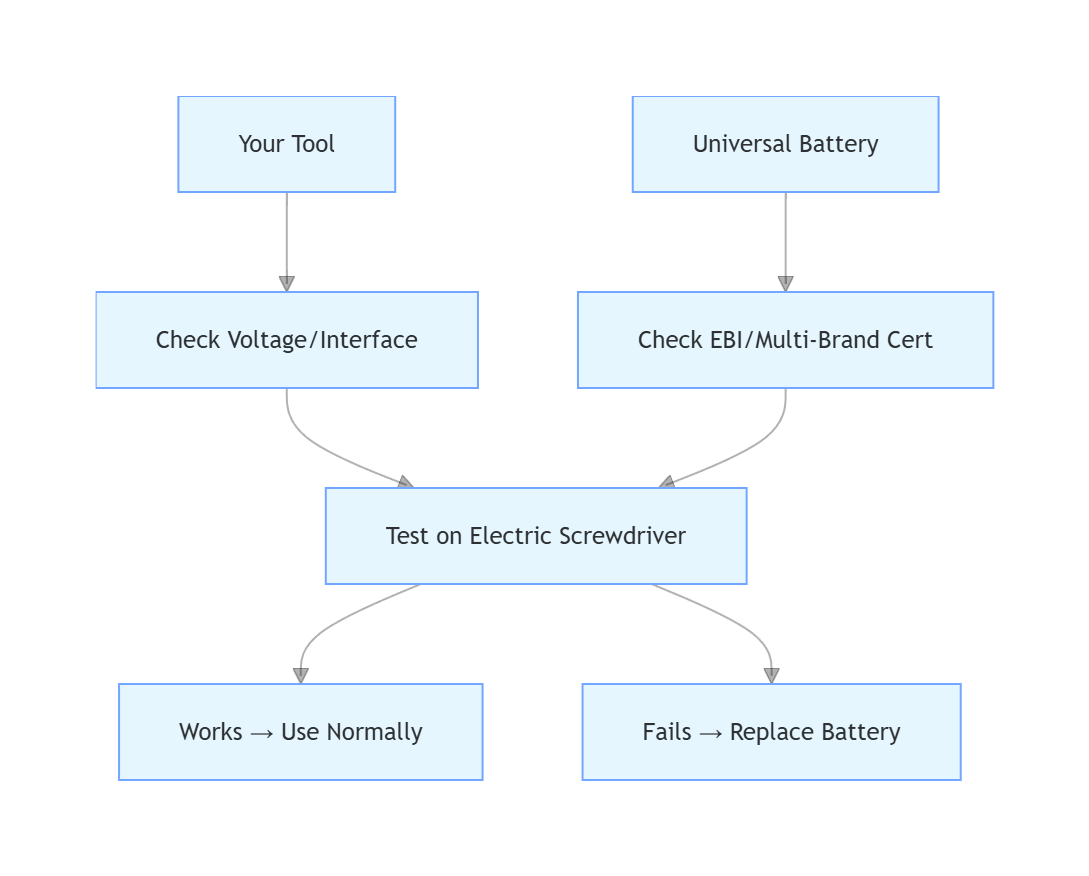

Solution 2: 3-Step Self-Check to Verify Battery-Tool Compatibility (Avoid “Fake Compatibility” Traps)

To avoid “fake compatibility” pitfalls, verify battery-tool matching through the following simple steps:

1.Check Tool Specs: Confirm voltage (18V/20V) and interface type (Slide-on/Pod-style);

2.Check Battery Cert: Ensure the battery has EBI or multi-brand certification;

3.Low-Power Test: First use on electric screwdrivers to avoid damaging high-cost tools.

The flowchart below simplifies the verification process:

Practical Tip: Blogger Sarah tested over 10 brands and found that batteries with “Smart Match” chips have 95% compatibility accuracy, much higher than ordinary universal batteries.

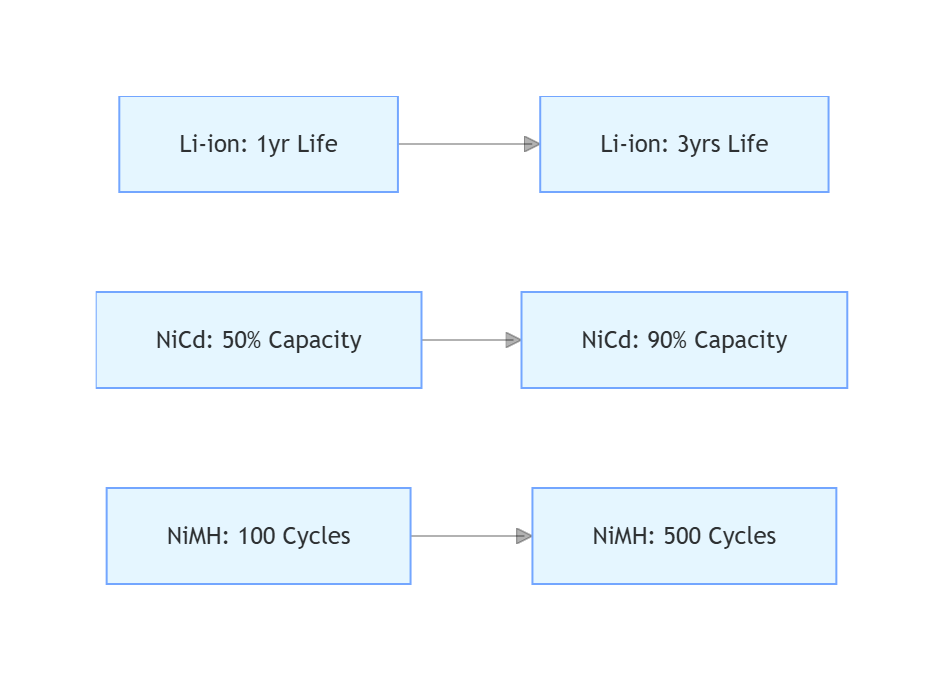

Solution 3: Maintain by Type to Extend Battery Life by 50%+

Different battery types require targeted maintenance. The table below lists key steps, and the flowchart shows the life improvement effect:

| Battery Type | Maintenance Cycle | Core Actions |

| Lithium-ion | Every 3 Months | When storing long-term, keep charge between 30%-80%; Avoid environments above 40℃ |

| NiCd | Monthly | Complete 1 full charge-discharge cycle monthly; Discharge to below 10% before long-term storage |

| NiMH | Every 2 Months | Avoid deep discharge (single cell voltage below 2V); Calibrate with a balance charger every 2 months |

Business Case: Hardware store owner Tom sent quarterly maintenance reminders to lithium battery customers and posted “battery maintenance guide posters” in the store. The average life of customers’ batteries extended from 2 years to 3.2 years, and the proportion of customers repurchasing original batteries dropped by 25% directly. The following diagram shows the difference before and after maintenance:

IV.Industry Case: How Standardization Reshapes the Power Tool Ecosystem?

The EBI (European Battery Interface) standard in the European market has shown initial results: Since 2025, power tool batteries that meet the EBI standard can be freely switched between 10+ brand tools such as Bosch, Festool, and Metabo. A German decoration company statistics show that after adopting EBI standardized batteries, tool procurement costs decreased by 30%, the types of battery inventory decreased by 70%, and the number of work stoppages due to “battery mismatch” dropped from 5 times a month to 0.

The Power Tool Interchange alliance in the North American market is also promoting “cross-brand battery interchange”: Brands like DeWalt and Stanley Black & Decker have promised to open part of the battery communication protocol, allowing third-party universal batteries to fit original tools more safely. Consumer reviews show that universal batteries certified by the alliance have less than 5% performance difference from original batteries on DeWalt drills, but the price is only 60% of the original.

V.Conclusion: Standardized Batteries, Free Your Power Tools

Power tool battery standardization in 2025 is not just an industry trend—it’s a tool for users to “break brand shackles”. From choosing “standardized certification + multi-brand compatible” universal batteries, to verifying compatibility through 3 steps and maintaining properly by type, every step helps reduce battery costs and extend lifespan without replacing tools.

If you still have questions like “Which universal battery to choose for a certain brand tool” or “How to judge if a battery meets standardization”, feel free to leave a comment, and we’ll provide customized advice based on tested data and industry reports.