When comparing NMC vs LiFePO4 batteries for industrial robots, the power supply system plays a critical role in performance, cost, and safety. As a core component of industrial robots, the power supply system directly determines operational efficiency, maintenance costs, and safety. This article systematically compares mainstream NMC (ternary lithium) and LiFePO4 (lithium iron phosphate) batteries through technical parameters, performance evaluations, scenario-specific applications, and industry trends, integrating practical industrial cases to provide actionable selection guidelines.

1. NMC vs LiFePO4: Technical Characteristics Comparison

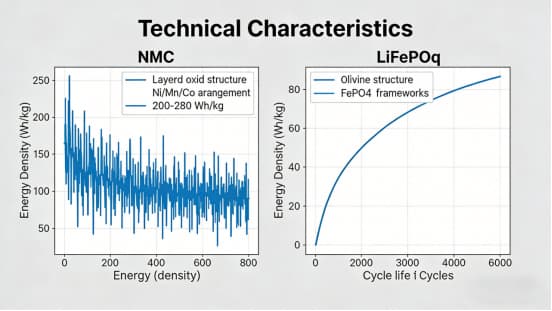

NMC batteries utilize nickel-manganese-cobalt ternary oxide cathodes, with adjustable element ratios (NCM523/622/811) forming stable electrochemical structures. Their primary advantage is high energy density: an AGV equipped with NMC batteries achieves 8 hours of continuous operation on a single charge, 30% longer than traditional alternatives. Advanced processes like surface coating and doping have enhanced cycle stability—NCM811 batteries retain 80% capacity after 1,500 cycles, suitable for medium-to-high-intensity tasks.

LiFePO4 batteries feature olivine-structured cathodes, ensuring exceptional chemical stability and resistance to thermal runaway—a critical safety advantage demonstrated when a damaged LiFePO4 battery pack in an auto parts factory remained intact after collision. Technological advancements (nanosized cathodes, optimized electrolytes) have boosted energy density from 120 Wh/kg to 140-180 Wh/kg. A fixed assembly robot using upgraded LiFePO4 batteries gained 25% longer runtime without space expansion, with a cycle life of 3,000-6,000 cycles (6 years of service in typical scenarios).

Technical Indicators | NMC Batteries | LiFePO4 Batteries |

Energy Density | 200-280 Wh/kg | 140-180 Wh/kg |

Cycle Life (≥80% capacity) | 1,500-2,000 cycles | 3,000-6,000 cycles |

Operating Voltage | 3.7v-4.2v | 3.2v-3.6v |

Operating Temperature | -20°C – 50°C | 0°C – 45°C |

Charging Efficiency | ≥ 95% | ≥ 98% |

Monthly Self-Discharge | 3-5% | 1-3% |

Note: NMC batteries excel in temperature adaptability, retaining ≥70% discharge capacity at -20°C and better cycle stability at 45°C than LiFePO4. LiFePO4 requires heating systems below 0°C due to significant capacity decay.

2. Comprehensive Evaluation of Performance Characteristics

NMC’s core strength lies in high volumetric energy density. A 50kg-load AMR with 250 Wh/kg NMC batteries uses an 8kg pack—4kg lighter than equivalent LiFePO4—reducing energy consumption and improving mobility. With BMS control, 1C fast charging (80% capacity in 30 minutes) suits high-frequency line changes: a 3C factory extended robot runtime by 2 hours daily, boosting productivity by 15%. Tradeoffs include 30% higher unit cost (per Wh) and shorter cycle life, increasing long-term replacement expenses.

LiFePO4’s key advantages are long lifespan and low maintenance. A logistics center’s handling robots saw annual maintenance drop from 4 to 1 time (60% cost reduction) after switching to LiFePO4. Stable voltage output (≤0.1V fluctuation) improved precision: an electronic assembly robot’s error rate fell from 0.3% to 0.1%. Low self-discharge (97% capacity retained after 3 months idle) benefits intermittent use—an auto factory’s 2-hour-daily spot welding robot showed no decay after 5 years.

Application Scenarios | Recommended Solution | Key Requirements | Case Reference |

AGV/AMR (Mobile Robots) | NMC | High energy density, fast charging, lightweight | E-commerce AGV: 10h runtime, 40min fast charge, 20% higher daily sorting |

Welding/Assembly (Fixed Robots) | LiFePO4 | Long cycle life, stability, low maintenance | Machinery factory robot: 6-year service, 4,000 cycles, 75% capacity retention |

Low-Temp Warehouses/High-Temp Workshops | NMC | Wide temperature adaptability | -15°C cold chain AGV: 75% capacity; 38°C workshop: better stability than LiFePO4 |

24/7 Production Lines (High-Frequency) | LiFePO4 | Long cycle life, low maintenance cost | Electronics factory: 3-year use, ¥80k lower replacement cost vs NMC |

3. Adaptation and Selection of Application Scenarios

For AGVs/AMRs, NMC’s energy density is critical. A port container AGV with NMC batteries reduced pack weight by 5kg, extended runtime to 12 hours, and increased daily throughput by 3 containers. In 3C assembly lines, NMC’s 1C charging (“30min charge = 4h work”) prevents production interruptions.

Fixed robots prioritize stability and lifespan. A vibration-prone auto parts welding robot ran 3 years fault-free with LiFePO4, vs 2 annual failures with prior batteries. Ten machinery factory assembly robots saved ¥30k/year in maintenance; LiFePO4’s total lifecycle cost is 40% lower than NMC.

Special environments highlight distinct strengths: NMC maintains 70% capacity at -18°C (vs 50% for LiFePO4) in northern cold chain warehouses. LiFePO4’s superior sealing resists dust/humidity—a furniture factory’s grinding robot operated 2 years without performance loss from dust ingress.

4. Implementation Strategies and Suggestions

Scientific battery selection requires a weighted evaluation system integrating production needs, environment, and budget:

Evaluation Dimension | Weight | Key Content | Practical Methods |

Energy Performance | 30% | Energy density, runtime | Calculate capacity needs; test simulated runtime |

Cycle Life | 25% | Cycle count, capacity decay | Review supplier data; survey industry peers |

Environmental Adaptability | 20% | Temperature range, protection level | Test in actual environment; verify protection rating |

Economy | 15% | Purchase, maintenance, lifecycle cost | Calculate 5-year total cost |

System Integration | 10% | BMS compatibility, scalability | Test BMS compatibility; assess expansion support |

Pilot testing is essential: a 100-AGV replacement project should first test 10 units (5 NMC, 5 LiFePO4) for 3 months, comparing runtime, charging speed, and maintenance. Prioritize NMC for cross-workshop AGVs (mobility/long runtime) and LiFePO4 for 24/7 fixed robots (low maintenance).

Establish dynamic maintenance: test capacity/efficiency quarterly, replace when capacity drops below 70%. Collaborate with suppliers for customization—e.g., optimized discharge rates for frequent start-stop robots, low-temperature electrolytes for cold environments.

System integration requires thermal/space planning: NMC generates more fast-charging heat (a 3C factory’s poor heat dissipation cut lifespan by 30%), while LiFePO4 needs optimized installation to avoid mobility impacts. Modular design enables flexible capacity adjustment—an auto factory scaled battery modules with production demands.

5. Industry Development and Standardization Construction

Standardization is urgent: incompatible interfaces cost one factory ¥500k when 100 LiFePO4 packs failed to fit new robots. Industry associations should unify test methods and interfaces. Technological innovation progresses rapidly: high-nickel NMC (NCM910) reached 320 Wh/kg in labs; silicon-carbon modified LiFePO4 improved low-temperature capacity by 20%.

In-depth integration of industry, university, research and application will accelerate the innovation of power supply technology. Currently, NMC batteries are developing towards high nickel content (such as NCM910), and their energy density is expected to exceed 300 Wh/kg. A high-nickel NMC battery developed by a university in cooperation with a battery enterprise has achieved an energy density of 320 Wh/kg in the laboratory, which will further improve the battery life when applied to robots in the future. LiFePO4 batteries focus on improving energy density and optimizing low-temperature performance. An enterprise has increased the low-temperature discharge capacity of LiFePO4 batteries by 20% through silicon-carbon anode modification, which is expected to expand its application in low-temperature scenarios.

Green manufacturing drives recyclability: NMC’s cobalt recovery hits 95% at leading enterprises; LiFePO4’s simpler recycling (no precious metals) saved one factory 30% on raw materials.

6. Advantages and Choices

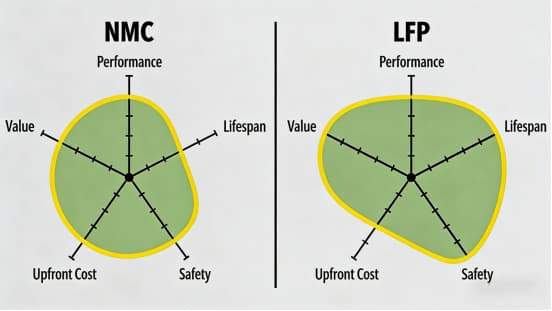

NMC and LiFePO4 serve distinct niches: NMC leads for mobile robots and extreme environments (high energy density, wide temperature range); LiFePO4 dominates fixed/high-frequency scenarios (long lifespan, low maintenance).

The core advantages of NMC batteries lie in their high energy density, long endurance, lightweight design, fast charging capability, and stable performance across both high and low temperature environments, making them well-suited for mobile devices. LiFePO4 batteries excel in safety and durability, featuring an extended cycle life, minimal maintenance requirements, slow self-discharge (retaining significant capacity even after prolonged inactivity), stable voltage output, and greater peace of mind for long-term use. The two battery types are tailored to different application scenarios—simply select the one that meets your specific needs!