Battery electrolyte is the critical core of robot power lithium-ion batteries—powering everything from industrial assembly robots and automated guided vehicles, or AGVs, to service robots in hospitals and outdoor inspection robots. Its role in enabling stable ion transport between electrodes directly determines whether a robot can maintain continuous operation, withstand mechanical vibrations, and adapt to variable working temperatures. For robot power systems, where reliability and durability are non-negotiable, the choice between liquid battery electrolyte, solid-state battery electrolyte, and hybrid battery electrolyte becomes a make-or-break factor for operational efficiency.

Liquid Battery Electrolyte: The Reliable Choice for Industrial Robot Power

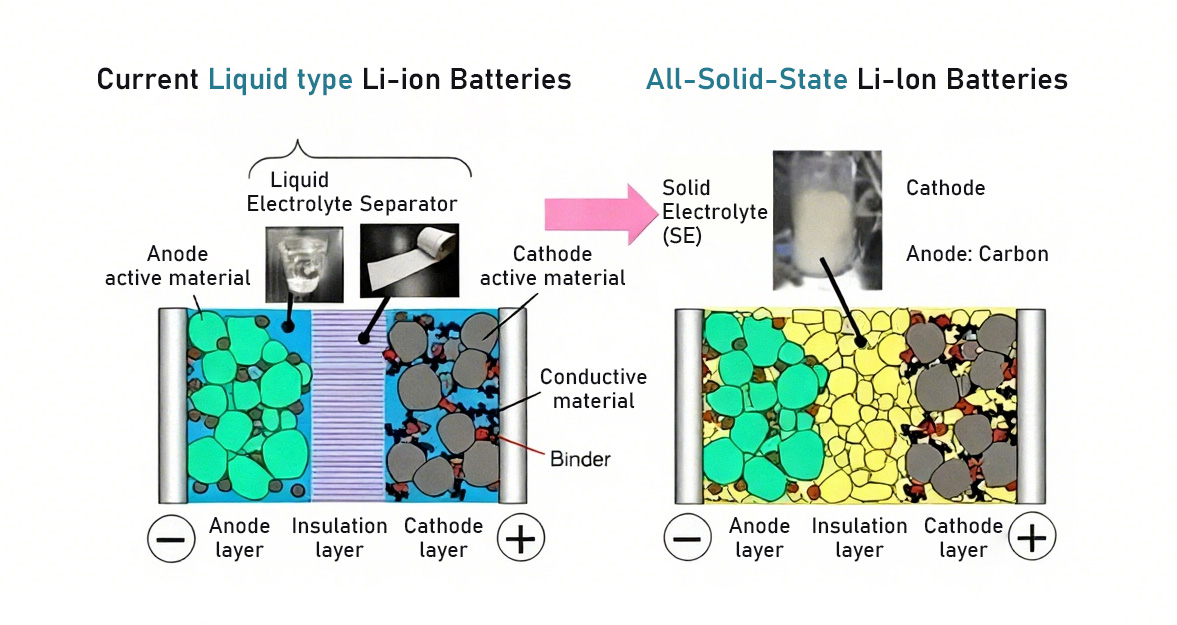

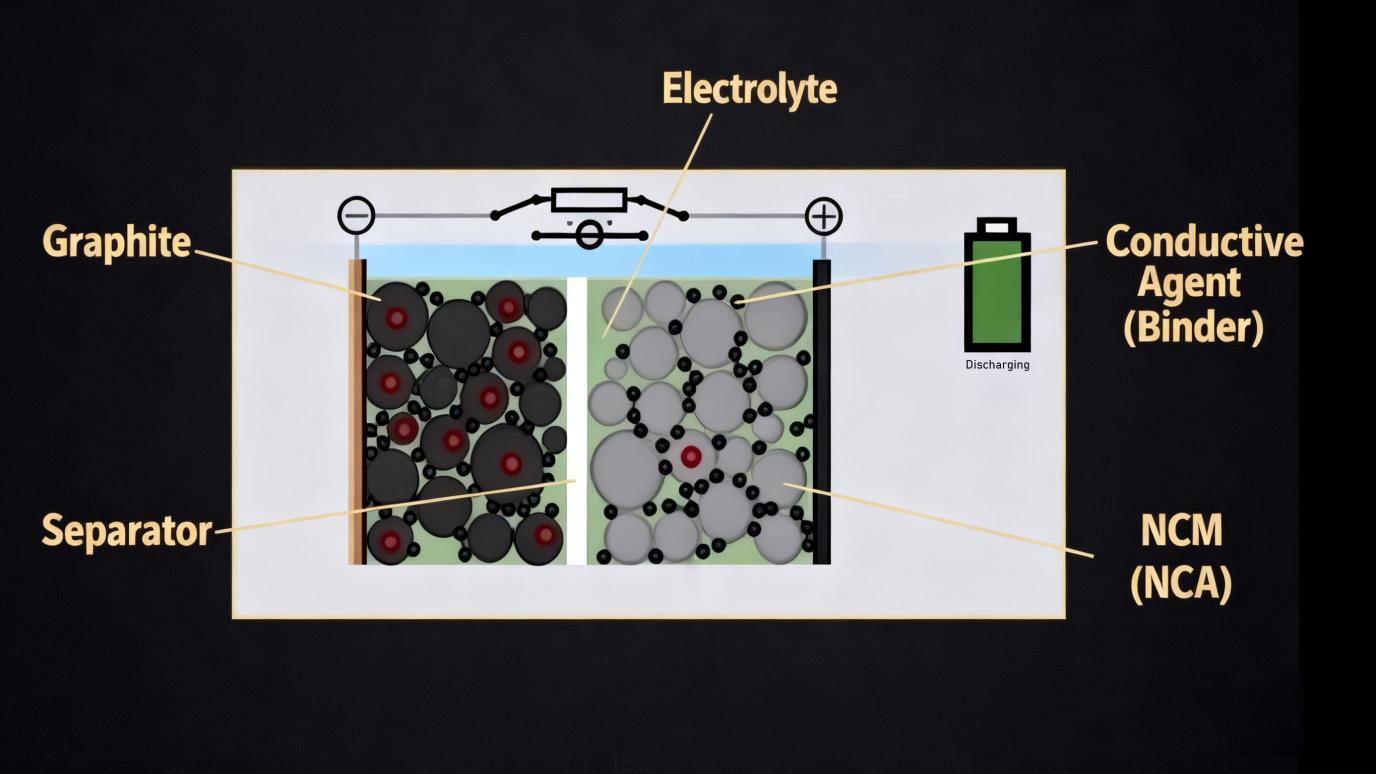

Liquid battery electrolyte, the most mature formulation in robot power lithium-ion batteries, consists of organic solvents such as ethylene carbonate and dimethyl carbonate, lithium salts such as LiPF₆ or LiFSI, and anti-oxidation/anti-corrosion additives. This composition delivers high ionic conductivity of 10-30 mS/cm at room temperature—a key requirement for robot power lithium-ion batteries that need to output instant high current during robot startup, lifting, or rapid movement.

Why Liquid Battery Electrolyte Fits Industrial Robots & AGVs

Industrial robots and AGVs operate in controlled environments like factories and warehouses but demand consistent performance over 8-12 hour shifts. Liquid battery electrolyte meets this need by:

•Supporting fast charging: Most robot power lithium-ion batteries with liquid electrolyte can recharge to 80% capacity in 30-45 minutes, minimizing downtime for AGVs in logistics yards.

•Withstanding mechanical stress: The fluid nature of liquid electrolyte buffers minor vibrations from robot arm movements, reducing electrode damage compared to rigid alternatives.

•Scaling cost-effectively: Mature production lines for liquid battery electrolyte enable robot manufacturers to source power lithium-ion batteries at stable prices, critical for mass-produced AGVs or collaborative robots.

Limitations for Specialized Robot Scenarios

Liquid battery electrolyte falls short in robots that operate in harsh conditions: outdoor inspection robots exposed to -20°C to 60°C temperatures may experience reduced conductivity in extreme cold, while medical service robots requiring zero fire risk face safety concerns from flammable organic solvents. These gaps have driven the need for advanced alternatives like solid-state battery electrolyte.

Solid-State Battery Electrolyte: Elevating Safety & Durability for Specialized Robots

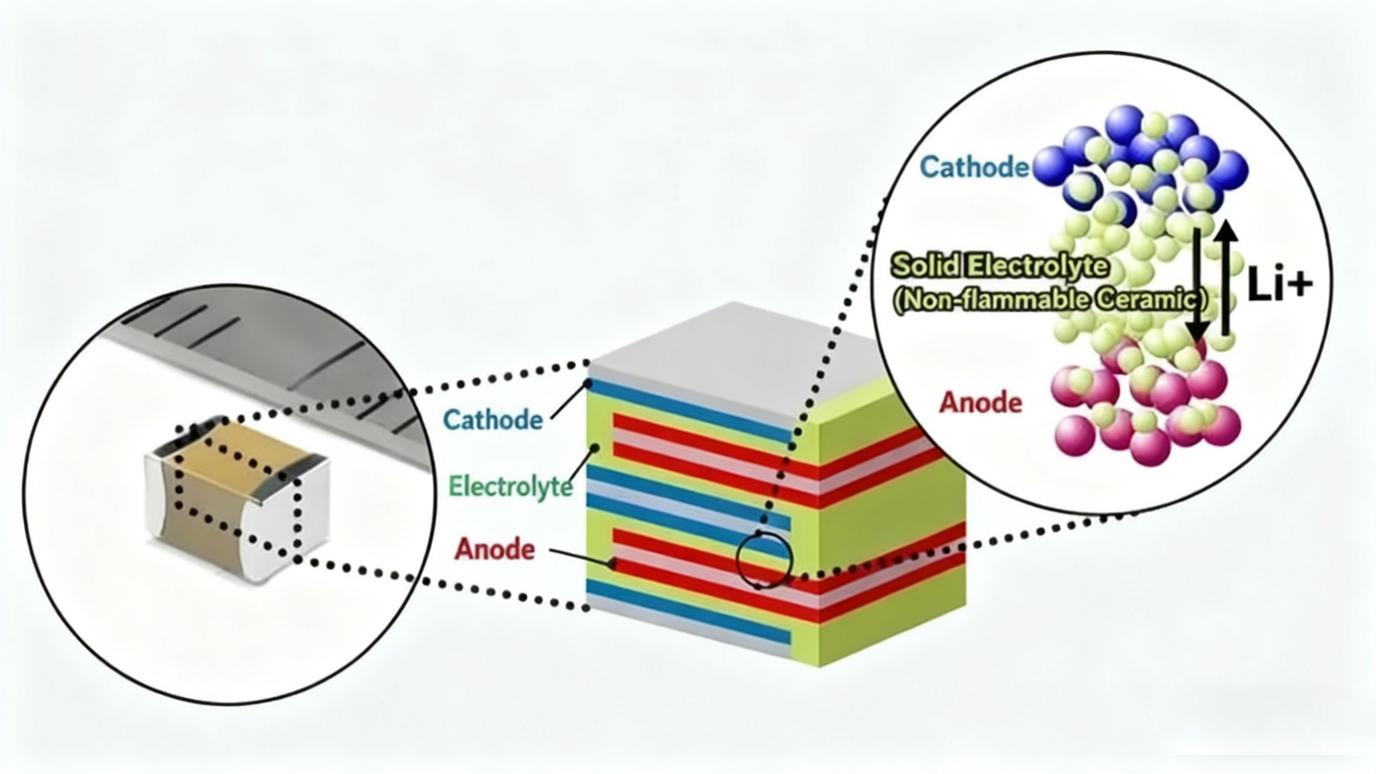

Solid-state battery electrolyte replaces liquid solvents with solid materials—typically ceramic materials like LLZO and LLTO or sulfide composites like Li₇P₃S₁₁—making it ideal for robot power lithium-ion batteries in high-risk or extreme-environment scenarios. Its non-flammable, leak-proof structure eliminates thermal runaway, a critical advantage for robots working near humans such as hospital service robots or warehouse robots handling chemicals.

Key Benefits for Specialized Robot Power Systems

For robot power lithium-ion batteries, solid-state battery electrolyte solves three major pain points:

1.Extreme temperature adaptability: Ceramic-based solid electrolyte maintains 80% of its conductivity at -30°C, enabling outdoor inspection robots like solar farm inspection robots to operate in winter.

2.Longer cycle life: Solid electrolyte reduces side reactions between electrodes and electrolyte, extending robot power lithium-ion batteries lifespan to 3,000+ charge cycles—double that of liquid-based batteries. This cuts maintenance costs for robots in remote areas such as pipeline inspection robots.

3.Compact design: Solid-state battery electrolyte pairs with lithium-metal anodes to create thinner, lighter power lithium-ion batteries, critical for small service robots like restaurant delivery robots where space and weight are limited.

Current Adoption Challenges in Robot Applications

Solid-state battery electrolyte is still scaling for mainstream robot use: its lower room-temperature conductivity of 1-20 mS/cm makes it less suitable for high-power industrial robots, and manufacturing costs remain 2-3x higher than those of liquid electrolyte. However, niche robot segments such as medical robots and aerospace inspection robots are already adopting it for safety-critical needs.

Hybrid Battery Electrolyte: The Balanced Solution for Versatile Robots

To bridge the gap between liquid and solid-state options, hybrid battery electrolyte has emerged as a game-changer for versatile robot power lithium-ion batteries. This formulation combines a solid ceramic framework for safety and structural stability with a dilute liquid electrolyte additive for boosted conductivity. For example, hybrid electrolyte in AGVs delivers 25 mS/cm conductivity, a level near that of liquid electrolyte, while remaining non-flammable—perfect for warehouses that require both fast charging and fire safety.

Ideal Use Cases for Robot Power

Hybrid battery electrolyte excels in robots with mixed demands:

•Mobile manipulation robots: These robots need high power for arm movements from the liquid additive and safety for human collaboration from the solid framework.

•Cold-chain AGVs: Hybrid electrolyte maintains conductivity at -25°C—better than liquid electrolyte—while avoiding the cost of pure solid-state electrolyte, making it suitable for frozen food warehouses.

Why Battery Electrolyte Defines Your Robot’s Performance

For robot manufacturers and integrators, choosing the right battery electrolyte for your power lithium-ion batteries directly impacts:

•Operational uptime: Liquid electrolyte reduces charging downtime for industrial robots; solid-state extends maintenance intervals for remote robots.

•Safety compliance: Solid-state or hybrid electrolyte meets strict safety standards for medical or food-processing robots.

•Total cost of ownership: Longer-lasting solid-state electrolyte cuts battery replacement costs; cost-effective liquid electrolyte suits high-volume AGV fleets.

As robots become more intelligent and versatile—from collaborative robots in factories to autonomous delivery robots on streets—battery electrolyte technology will continue to evolve. Optimizing liquid formulations for extreme temperatures, scaling solid-state production for affordability, and refining hybrid designs will unlock new possibilities for robot power lithium-ion batteries, ensuring robots can operate longer, safer, and more efficiently than ever before.