Certified ISO 9001 lithium battery solutions are engineered to deliver consistent quality, safety, and compliance for demanding global applications — from electric vehicles and grid-scale energy storage to industrial and portable power systems. At Febatt, this certification is not just a badge; it’s the backbone of our quality management system (QMS), ensuring every battery we produce meets the highest international standards.

ISO 9001, the global standard for quality management systems (QMS), is our foundation for delivering consistent, high-quality lithium battery solutions, ensuring we meet customer, regulatory, and internal requirements. With over 1 million certified organizations across 170+ countries, it’s the only certifiable standard in the ISO 9000 series.

Why Certified ISO 9001 Lithium Battery Solutions Matter?

ISO 9001 is the world’s most widely recognized standard for quality management systems (QMS), adopted by over 1 million organizations across 170+ countries. For B2B partners sourcing lithium battery solutions, choosing a supplier with certified ISO 9001 lithium battery solutions means guaranteed consistency, regulatory compliance, and operational excellence.

As the only certifiable standard in the ISO 9000 family, ISO 9001 ensures that every stage — from design and production to testing and delivery — is rigorously controlled, traceable, and continuously improved.

What Is ISO 9001? The Global Standard for Quality

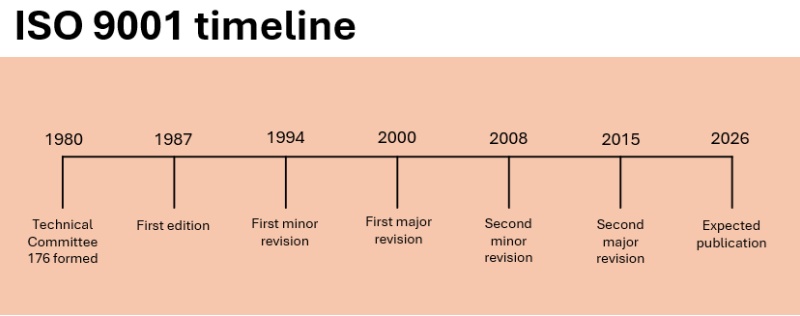

First introduced in 1987 by the International Organization for Standardization (ISO), ISO 9001 defines the requirements for a robust QMS that ensures consistent product quality. In the context of lithium-ion batteries — used in EVs, renewable energy storage, and high-performance devices — this standard acts as a structured control framework, much like a battery management system (BMS) for operations.

It supports critical compliance processes such as UL, CE, and UN38.3 certifications, and is reviewed every five years to stay aligned with technological and industrial advances. The next update is expected in 2026.

For engineers, ISO 9001 may seem technical at first — like decoding a dense spec sheet — but once understood, it brings clarity and predictability to complex manufacturing environments.

How ISO 9001 Has Evolved to Meet Battery Industry Needs

ISO 9001 adapts to industry demands:

- 1994: Strengthened design and development controls, crucial for lithium battery innovation; clarified roles of ISO 9002 and 9003.

- 2000: Shifted to a process-based model, merging 9002/9003; emphasized leadership engagement, performance metrics, and continual improvement, aligning with efficient battery production.

- 2008: Provided clarifications to enhance the 2000 version’s application, streamlining implementation.

- 2015: Introduced risk-based thinking to address challenges proactively, improved applicability for services, and strengthened leadership requirements, supporting Febatt’s innovation-driven approach.

- 2024 Update (ISO London Declaration): Added requirements in Clauses 4.1 and 4.2 to assess how climate change impacts QMS outcomes. While this supports sustainable lithium battery solutions, it must be carefully scoped to avoid diverting focus from core quality objectives.

At Febatt, sustainability is already embedded in our designs — from eco-friendly materials to recyclable battery systems — making this update complementary, not disruptive.

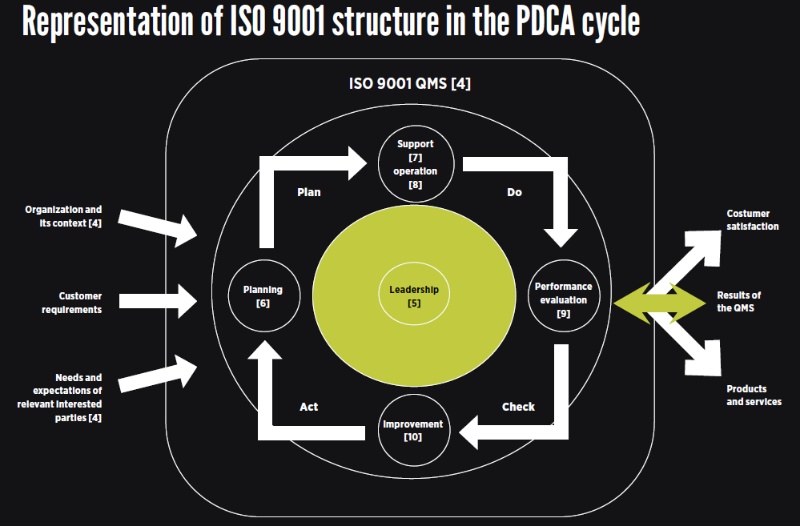

Core Structure of ISO 9001: A PDCA Framework for Battery Excellence

ISO 9001 is built on the Plan-Do-Check-Act (PDCA) cycle — an iterative model similar to a feedback loop in a BMS, constantly optimizing performance.

The standard consists of eight sections, with five key implementation clauses that directly impact lithium battery production:

- Section 4: Context of the Organization

Analyze internal and external factors, such as climate change or market demands for high-capacity batteries, and define QMS scope and processes to support battery certification. - Section 5: Leadership

Ensure top management champions quality, aligning the QMS with strategic goals like developing cutting-edge power battery solutions. - Section 6: Planning

Identify risks (e.g., supply chain disruptions for battery materials), set objectives for performance and safety, and plan QMS changes systematically. - Section 7: Support

Provide resources, ensure workforce competence, and maintain documented information for lithium battery production and certification. - Section 8: Operation

Manage the product lifecycle—from battery design to production and delivery—ensuring compliance with standards like UL, CE, and UN38.3. - Section 9: Performance Evaluation

Conduct internal audits, monitor customer satisfaction (e.g., feedback on battery reliability), and analyze data to optimize performance metrics like cycle life and charge efficiency. - Section 10: Improvement

Address nonconformities (e.g., defective cells) and drive continuous improvement in battery solutions.

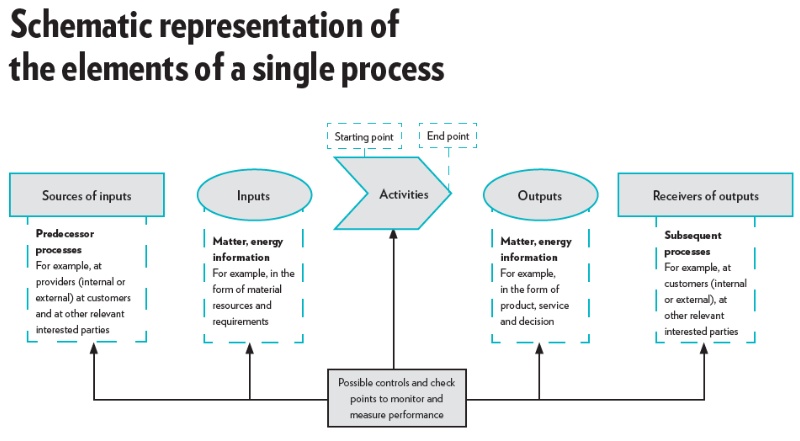

The process approach—transforming inputs into value-added outputs—is like optimizing a battery assembly line. It’s rigorous yet flexible, allowing Febatt to tailor processes to our needs, such as high-energy-density battery production or rigorous safety testing.

Key Benefits of Certified ISO 9001 Lithium Battery Solutions

Implementing a robust QMS delivers tangible advantages for both manufacturers and buyers:

- ✅ Consistency: Ensures our lithium batteries meet customer expectations and regulatory standards (e.g., UL, CE, UN38.3), critical for safety and performance.

- ✅ Stakeholder Trust: Boosts confidence among customers relying on our power battery solutions for electric vehicles, grid storage, or consumer electronics.

- ✅ Risk Management: Proactively mitigates risks, such as material defects or production delays, which are make-or-break in battery manufacturing.

- ✅ Efficiency: Streamlines processes, reducing waste and costs in lithium battery production, from raw material sourcing to final assembly.

- ✅ Credibility: Battery certification enhances Febatt’s reputation in the competitive global energy market, opening doors to new partnerships.

For Febatt, ISO 9001 is more than compliance — it’s the foundation of our reputation as a trusted provider of certified ISO 9001 lithium battery solutions.

How to Achieve ISO 9001 Certification for Battery Manufacturing

To implement ISO9001:

- Purchase the Standard: Available from ISO, applicable to any organization, including Febatt’s battery operations.

- Build the QMS: Align processes with ISO 9001 requirements for lithium battery production and certification, covering design, testing, and manufacturing.

- Ensure Compliance: Meet internal, customer, and regulatory standards, such as those for battery safety, performance, and transportation.

- Document Processes: Maintain detailed records for certification audits, documenting everything from cell design to quality control checks.

- Pass an Audit: Achieve certification through a registrar’s audit, verifying QMS effectiveness and compliance.

- Maintain & Improve: Continuously evaluate and enhance your system based on feedback and data.

💡 Cost Considerations:

- Audit Fees: For registration, surveillance, and recertification audits, ensuring ongoing compliance.

- Compliance Efforts: Resources to align with ISO 9001, such as upgrading testing equipment or training staff.

- Internal Effort: Staff time to develop and implement the QMS, from engineers to quality assurance teams.

- Consultants: Optional external expertise for navigating complex battery certification processes.

While certification requires investment — akin to upgrading lab testing equipment — the return in quality assurance, market access, and customer trust is transformative.

Engineer’s Perspective: ISO 9001 as the BMS of Quality Management

To me, ISO 9001 functions like a well-calibrated battery management system (BMS) — monitoring, controlling, and optimizing every aspect of our operations. It ensures our lithium battery solutions deliver stable voltage, long cycle life, and fail-safe performance.

The standard’s rigor guarantees consistency, but let’s be honest: the documentation burden can feel like running diagnostics on every single cell — necessary, but sometimes excessive for agile teams.

Still, the benefits far outweigh the overhead. For instance, our focus on preventing thermal runaway through rigorous testing aligns perfectly with ISO 9001’s risk-based thinking. Early detection of inconsistent cell quality saves time, cost, and potential recalls.

Yes, the 2024 climate change clause adds complexity — but at Febatt, we already design for sustainability. When integrated wisely, it enhances rather than distracts from our core mission: delivering certified ISO 9001 lithium battery solutions you can trust.

Final Thoughts: Powering the Future with Certified Quality

In the fast-evolving world of energy storage and electrification, quality isn’t optional — it’s existential. Certified ISO 9001 lithium battery solutions represent more than compliance; they reflect a commitment to excellence, safety, and continuous innovation.

For global B2B partners, choosing a manufacturer with ISO 9001 certification means reduced risk, faster time-to-market, and stronger brand alignment.

At Febatt, we don’t just meet the standard — we live it. Because when your battery powers a vehicle, a city, or a life-saving device, there’s no room for compromise.

📞 Ready to partner with a trusted provider of certified ISO 9001 lithium battery solutions?